3D printing has been in existence for a long period of time. It was introduced by Charles W. Hull in the 1980s. 3D printing has seen great consistent development over years. This has been influenced by great technology development in the centuries. With this development you can easily access commercial 3d printing services across the markets. Various models and shapes have been made possible through the advancement n the 3D printing technology. In this article we are going to look at How 3D printing works, the types of 3D printers and its applicability’s.

How does 3D printing work?

First of all the 3D object is modelled and sliced ready for 3D printing. At this point the 3D printer takes over the printing process. The 3D printer nozzle, moves back and forth smearing polymers or wax upon every layer. It is programmed using a CAD system to ensure that there is accuracy of layer printing and time. It adds polymers to the 2D layer until it achieves the 3D layer.

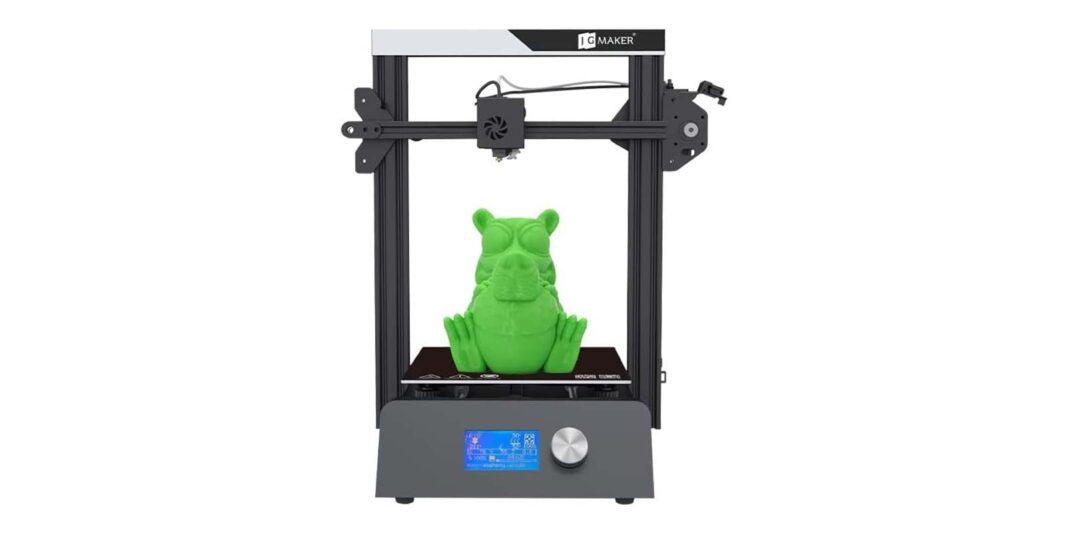

Types of 3D printing machines

There are different types of 3D. They vary in shapes and capacity. However they all serve a great purpose as far as 3D printing is concerned. They include;

Stereolithographic 3D printing machine- SLA

This printer is commonly known as SLA printers. They convert the Liquid resins into plastic. This is due to the influence of laser incorporated in the machine.

Selective laser sintering – SLS

Do you need to add more layers into a solid structure? Selective laser sintering printer is equipped with a laser whose function is to sinter polymer powder into an already solid object.

Fused deposition modelling machine-FDM

These printers produce thermoplastic filaments that are passed through a nozzle which moulds them to form layers of objects.

Where is 3D printing applicable?

3D printing can be applied in various sectors in the market. Additionally, it is predicted that in few years to come 3D will have transverse every sector of the economy. There is therefore a need to learn and incorporate it in every sector.

Rapid prototyping

In the manufacturing industry, there is a lot of testing. This is called prototyping. It is a process that checks if the product has achieved the envisioned qualifications before it is customized. 3d printing in this case offers a cheap and rapid prototyping service.

Manufacturing

After the prototype has been verified then the product is ready for massive manufacturing. This has seen huge units of production in the manufacturing industry.

Repair and replacement

3D printing has made repairs and replacements easy and affordable. This is because worn out layers can be added into the solid objects with the 3D printing machines.

Medicine

In the field of medicine, great technological advancements have been achieved. Departments such as ICU and dentistry have seen great influence in 3D printing technology. With the rise of Covid-19 saw ventilator products and PPEs were developed through the 3D printing technology.

Conclusion

3D printing machines has a great influence in every sector of the market and since the world is in a progressive technology, 3D printing will have a great impact in the future too. It is worth embracing and incorporating 3D printing into other sectors of the economy.